The tobacco industry relies heavily on attractive and functional packaging to maintain product quality and capture customer attention. Among these packaging solutions, empty cigarette boxes stand out as a critical component, serving both practical and branding purposes. But what materials are used to create these boxes, and how does custom product packaging enhance their appeal? In this comprehensive article, we’ll delve into the various materials used to manufacture cigarette boxes, exploring their properties, benefits, and the trends driving innovation in the industry.

The Purpose of Empty Cigarette Boxes

Empty cigarette boxes are far more than mere containers. They perform several essential functions that make them indispensable in the tobacco market. The primary purpose is to protect cigarettes from external damage, including physical impacts, moisture, and environmental contaminants. Without durable and well-designed packaging, cigarettes would lose their freshness and structural integrity, affecting the consumer experience.

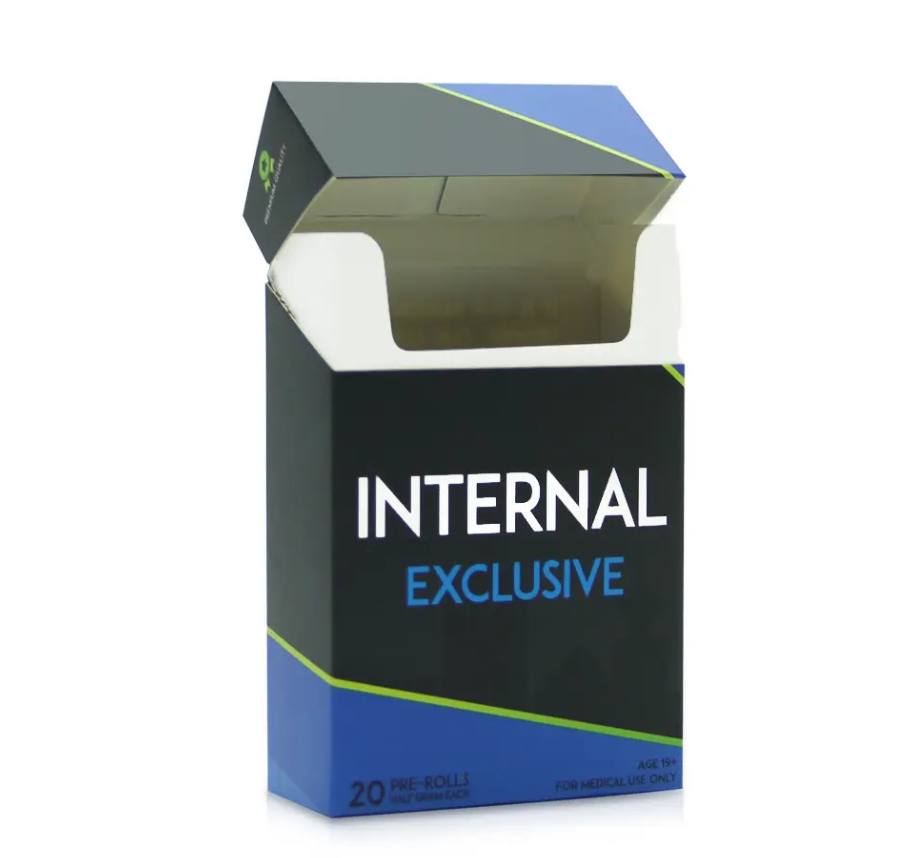

In addition to protection, these boxes are a powerful tool for branding. Companies use custom product packaging to create visually appealing designs that reflect their brand identity, appeal to target audiences, and comply with government regulations. Whether it’s through bold colors, sleek designs, or health warnings, cigarette boxes act as silent brand ambassadors.

Lastly, portability is another critical factor. Cigarette boxes are designed to be compact and lightweight, making them convenient for consumers to carry. The materials used in their production ensure that these boxes maintain their functionality while staying stylish and easy to handle.

Key Materials Used in Empty Cigarette Boxes

To meet the diverse requirements of protection, branding, and portability, manufacturers use a range of materials to create empty cigarette boxes. Here are the most common ones:

1. Cardboard

Cardboard is the most widely used material for cigarette boxes. It is lightweight yet sturdy, making it an ideal choice for bulk production. Cardboard offers excellent printing capabilities, allowing brands to add vibrant designs, logos, and health warnings. Additionally, it is cost-effective and recyclable, making it a popular choice for custom product packaging.

Cardboard boxes are also versatile, offering various thickness levels to suit different packaging needs. For instance, premium cigarette brands may use thicker cardboard for a more luxurious feel, while budget-friendly options often use thinner material.

2. Kraft Paper

For brands looking to align with eco-friendly values, kraft paper is an excellent choice. This biodegradable and recyclable material is made from wood pulp, offering a natural and rustic appearance. Kraft paper is especially popular among companies that want to project a sustainable image or target environmentally conscious consumers.

In terms of functionality, kraft paper provides adequate protection for cigarettes while being lightweight and easy to customize. Whether it’s plain brown kraft or bleached white variants, this material supports various design possibilities for custom product packaging.

3. Metalized Paperboard

For a premium and luxurious look, many cigarette brands turn to metalized paperboard. This material features a metallic finish that enhances the aesthetic appeal of empty cigarette boxes. Metalized paperboard is often used for limited-edition packaging or high-end brands aiming to create a sophisticated image.

Apart from its visual appeal, metalized paperboard is durable and resistant to moisture, ensuring that the cigarettes remain fresh and intact. The shiny surface also provides an excellent base for printing intricate designs, making it a favorite for custom product packaging that stands out on shelves.

4. Plastic

While the use of plastic in cigarette boxes has decreased due to environmental concerns, it still finds application in certain contexts. Plastic offers unparalleled durability and resistance to water, making it suitable for harsh environments. However, its lack of sustainability has prompted many companies to shift towards greener alternatives.

When used, plastic is often combined with other materials to provide additional strength or transparency. For instance, a plastic window might be added to a cardboard box to showcase the product inside.

Why Material Selection Matters in Custom Product Packaging

The choice of materials plays a critical role in the success of custom product packaging for cigarette boxes. Here’s why:

Durability:

Materials like cardboard and metalized paperboard offer excellent protection against physical damage and moisture, ensuring that cigarettes stay fresh and intact. Durable packaging not only enhances the consumer experience but also reduces wastage, making it a cost-effective solution.

Sustainability:

With growing awareness about environmental issues, consumers and regulators alike are demanding sustainable packaging options. Materials such as kraft paper and recyclable cardboard allow companies to meet these expectations while maintaining their brand image.

Brand Identity:

Packaging is often the first point of contact between a brand and its customers. By choosing materials that support vibrant printing and creative designs, companies can create memorable empty cigarette boxes that reflect their identity and appeal to their target audience.

The Role of Customization in Cigarette Packaging

Customization is a key trend in the packaging industry, and cigarette boxes are no exception. With advancements in printing and design technologies, brands can now create highly personalized packaging that resonates with their audience. Here are some common customization techniques:

Embossing and Debossing:

These techniques create a tactile experience by raising or recessing elements like logos or brand names. They add a touch of sophistication to empty cigarette boxes, enhancing their premium appeal.

Foil Stamping:

Foil stamping involves applying metallic foil to certain parts of the packaging, such as logos or borders. This technique is often used in custom product packaging to create a luxurious look.

Unique Shapes and Sizes:

While standard cigarette boxes are rectangular, some brands experiment with unique shapes and sizes to stand out. Customizing the box shape can also enhance functionality, such as adding compartments or windows. More

Trends in Material Choices for Empty Cigarette Boxes

The packaging industry is evolving rapidly, driven by consumer preferences and regulatory changes. Here are some trends shaping the materials used for empty cigarette boxes:

1. Sustainability:

The shift towards eco-friendly packaging is perhaps the most significant trend. Companies are increasingly opting for materials like kraft paper and recyclable cardboard to reduce their environmental footprint. Some are even exploring innovative materials like hemp-based paper.

2. Minimalism:

Modern consumers prefer clean and simple designs, which has led to a rise in minimalist packaging. Materials that support subtle textures and muted colors are gaining popularity in custom product packaging.

3. Technological Integration:

Smart packaging solutions, such as QR codes printed on boxes, require materials that can accommodate high-quality printing. Cardboard and metalized paperboard are ideal for this purpose, enabling brands to connect with consumers digitally.

Conclusion

The materials used to create empty cigarette boxes are crucial to their functionality, aesthetics, and sustainability. From the cost-effectiveness of cardboard to the eco-friendly appeal of kraft paper and the luxurious feel of metalized paperboard, each material brings unique advantages to the table. As the packaging industry continues to evolve, trends like sustainability and customization are driving innovation in material selection and design.

By understanding the properties of these materials and leveraging the power of custom product packaging, brands can create cigarette boxes that not only protect the product but also captivate consumers. Whether you’re a tobacco company or a packaging supplier, investing in the right materials can set your product apart in a competitive market.Looking for innovative packaging solutions? Explore options for empty cigarette boxes tailored to your brand needs and let custom product packaging elevate your business to the next level.